Deze website is uitsluitend bestemd voor personen werkzaam in de handel van tabaks- en aanverwante producten. U wordt gevraagd naar waarheid te bevestigen dat u werkzaam bent in de handel van tabaks- en aanverwante producten. Het raadplegen van de inhoud van deze website door personen die niet werkzaam zijn in de handel van tabaks- en aanverwante producten is verboden.

As professionals, we continuously strive to achieve quality. We produce tens of thousands of bottles of e-liquid at our plant in Oosterhout on a daily basis. This traditional process is meticulously carried out by craftspeople.

Our production process starts with the composition of the basic liquid, also known as the base, which is measured to the nearest hundredth of a gram and whose nicotine content is extensively analysed for each batch of e-liquid. The production process is carried out by our specialists with the greatest possible care. From mixing the basic ingredients to inspecting the final products. All of which is executed in accordance with the ISO 9001 standard.

Craftspeople & specialists

In addition to the craftspeople involved in production, our team consists of specialists in the fields of the TPD, CLP and related legislation. They continually endeavour to update all our products. Given that we operate in a relatively new industry, the legislation applicable remains subject to change. This prompted us to outsource the printing of all our packaging and labels to Dutch printers; this allows us to respond quickly whenever changes need to be made.

As a recognised apprenticeship company, we are also directly involved in training the professionals of the future. This approach enables us to share our knowledge with apprentices, while also vouching for the craft involved in the production of traditional Millers Juice e-liquids.

Own laboratory

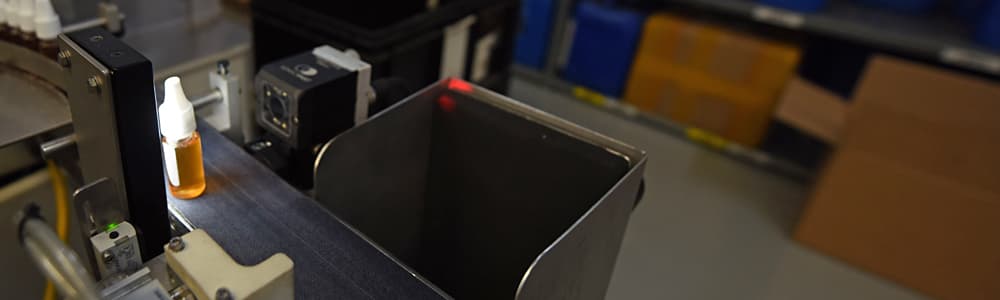

High-quality products rely on close monitoring. We therefore have our own laboratory, which vouches for our products' compliance with the stringent Dutch standards applicable. It carries out numerous daily tests on the e-liquids that we produce. This starts with the raw materials, the purity of which we establish before proceeding to process them. Following production, the nicotine content and emission of our e-liquids are monitored, enabling us to continually assure customers of the quality of the products they purchase.

Our laboratory is equipped with the latest equipment, with which to perform the best possible quality control. The combined guarantees of full traceability and the ISO 9001 certificate greatly assist in our endeavour to continually manufacture the highest quality product. For example, we apply GC-MS (Gas Chromatography – Mass Spectrometry) and HPLC (High Pressure Liquid Chromatography) to establish highly accurately which substances are contained in our e-liquid.

Emissions

We also have what is known as a puffing machine, which is used to check the emissions of e-cigarettes. As the registration of emission reports is mandatory throughout the European Union, possession of this equipment is ideal for internal reporting, analysis and registration purposes.

In addition to our laboratory work, we participate in various NEN, CEN and ISO working groups, with a view to establishing the European and international standards. For example, we collaborate with the CEN (European Committee for Standardization) working group in the interest of improving the registration and testing method of e-cigarettes and e-liquids. Furthermore, we cooperate with the NEN Committee in its efforts to establish general legislation and registration.

Our craftsmanship is a continuous learning process, while we also inspect our products in our own laboratory on a daily basis. This helps us to continually improve and focus sharply on meeting both our own and generally applicable standards.

Own laboratory

In addition to a major manufacturing plant in Oosterhout, we have our own distribution centre, which holds ample stock and carries out swift handling. The centre ships products to numerous (wholesale) dealers worldwide. Our application of an innovative combination of pick-to-light and pick-to-cart systems enables us to invariably pick orders swiftly and with the utmost precision, while close cooperation with international carriers vouches for short delivery periods.